It’s crucial to promptly establish and deal with high-quality problems to mitigate their impact on affected individual basic safety and product quality; well timed CAPA actions support protect against prospective damage and decrease the scope of troubles.

Do: Carry out the action plan by carrying out the chosen Remedy and carefully checking its performance. Taking action is critical to bring the plan to existence.

Preventive action is a measure a company normally takes to forestall any nonconformity to a corporation's primary intentions.

Documentation information the entire approach, demonstrating compliance with regulatory requirements and serving like a reference for foreseeable future audits or inspections.

A corrective action ask for or Auto is often a element of producing or creation policies. It might be the result of an audit, client issues, or simply a generation line incidence.

CAPA reporting assists an organization build a databases of corrective and preventive actions in opposition to frequent and predicted complications. The documentation of action plans,aside from supporting avoid related difficulties Sooner or later, also assist with personnel accountability.

Using the sampling tables, choose and evaluate documents of The newest corrective or preventive actions (this sample may possibly consist of or contain documents from your Formerly selected sample of important corrective actions).

As a proper request, Car or truck aims to remove all resources of nonconformity. Production nonconformity normally stems within the solution or manufacturing approach.

Non-conformance is obvious just after systematic Examination and evaluation of the foundation cause of the nonconformance.

Threat Evaluation and Prevention Planning - Conduct a danger assessment to detect likely long run hazards or equivalent nonconformances/non-compliances. Establish preventive action plans geared toward stopping similar concerns from developing Down the road.

2. Figure out if get more info ideal sources of merchandise and excellent problems happen to be recognized. Validate that info from these resources are analyzed to establish present products and quality problems that could demand corrective action.

You may also be needed to outline the roles and responsibilities of stakeholders involved with the CAPA approach.

Action is taken to do away with the cause of a possible nonconformity, defect or other undesirable situation, in an effort to click here avert occurrence.

Errors generally occur because of an absence of coaching, knowledge, or powerful procedure. CAPA reports supply proactive options to expected mistakes and decreased their chance of recurrence.

Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Christina Ricci Then & Now!

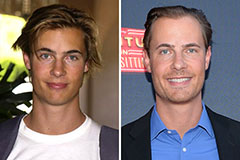

Christina Ricci Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now!